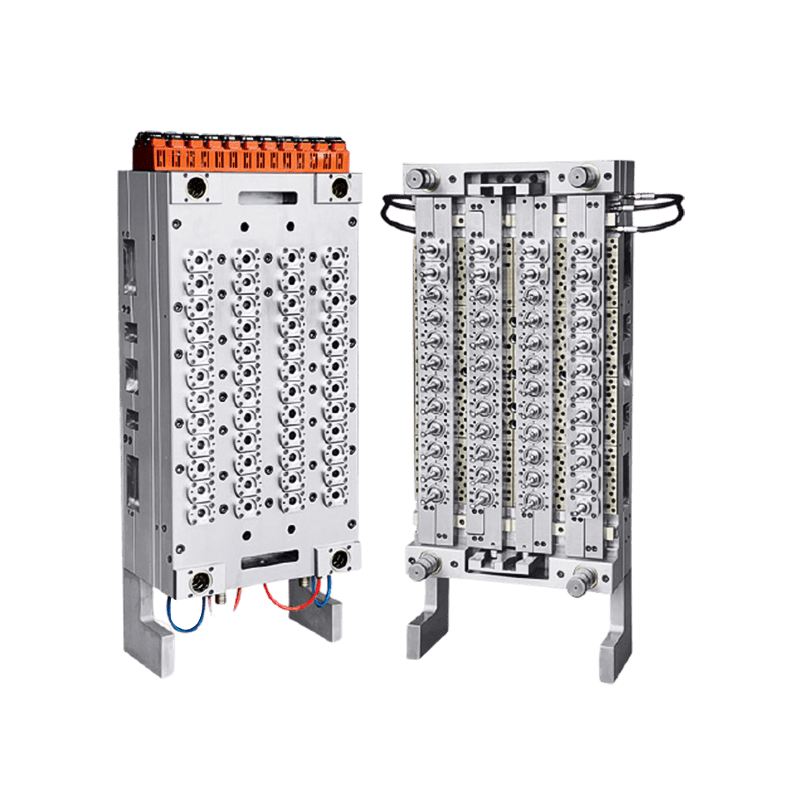

模具特征

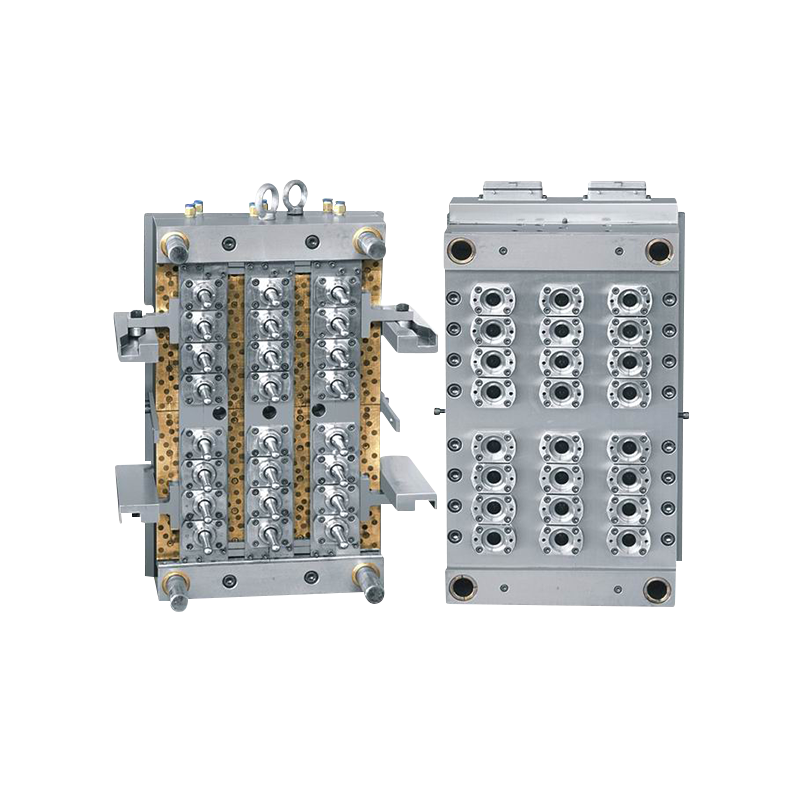

Mould plates are P20 steel with pre-hardening process. Core, cavity and neck screw are made of S136 high Strength, anti-corrosive stainless steel. Mould plate is completed by one-time processing to ensure the concentricity of moulding hole and guide bush, guaranteeing the compact structure of mould.

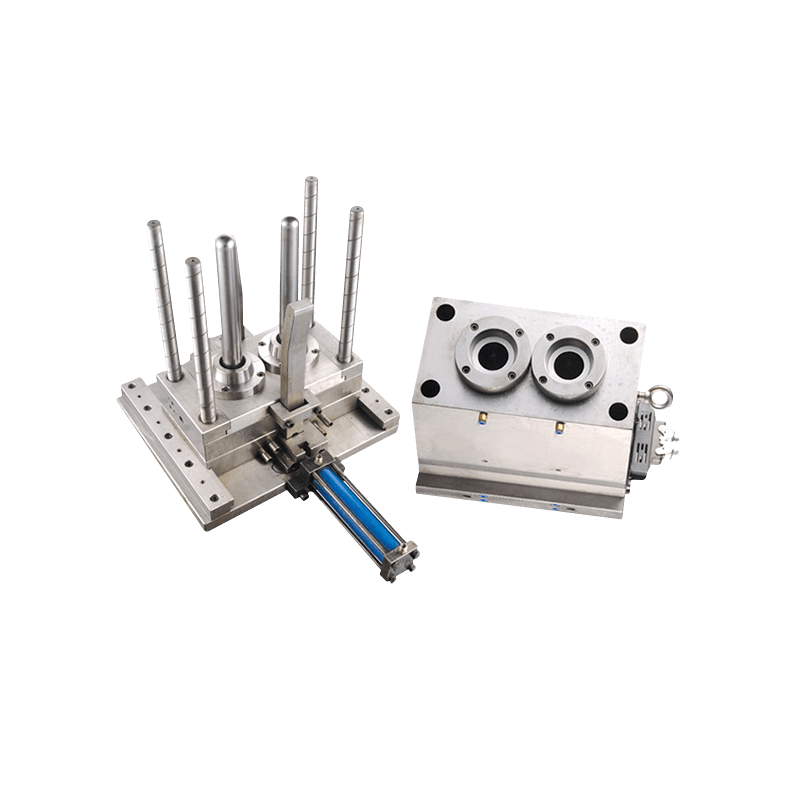

Fountain or spiral cooling structure is used in the core.

Spiral waterway is used to milled outside the cavity,improve cycle efficiency and reduce cleaning times.

Neck drilled cross cooling channel.

Each plate is individually designed with a circulation cooling channel.

Optimized cooling layout is used to ensures fast and efficient heat exchange between steel and water and support fast cycle times to save energy costs.

Experienced designers design preform mould with the help of computer according to the final bottle shape; Preform thickness and height is reasonably and perfectly designed to ensure the final bottles weight light but feel hard.

Weight variation across cavities is minimal.

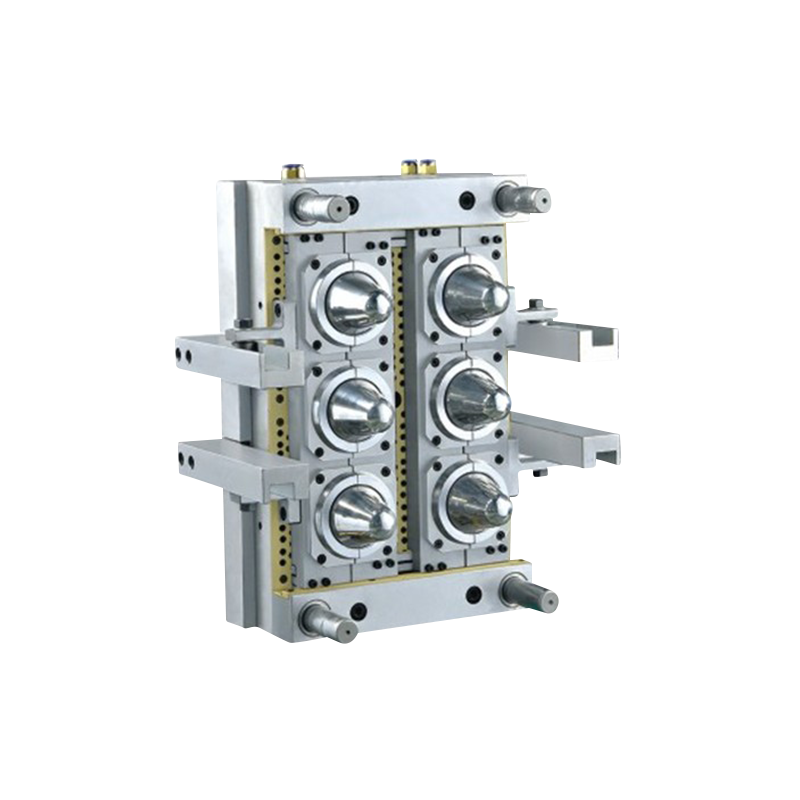

Excellent concentricity between core and cavity for minimum wall thickness variation.

Good mould life due to perfect matching of components under load.

Off-center adjustment system to ensure preform thickness difference < 0.10mm.

Self- lock individually for each cavity to guarantee high precision and less defect of the final preform production and also convenient disassembly.

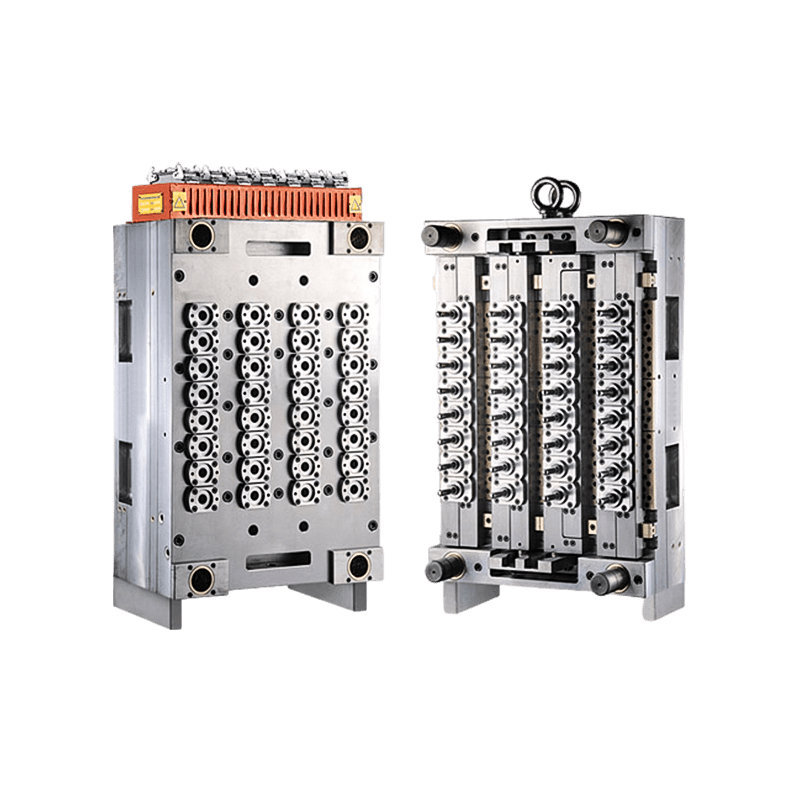

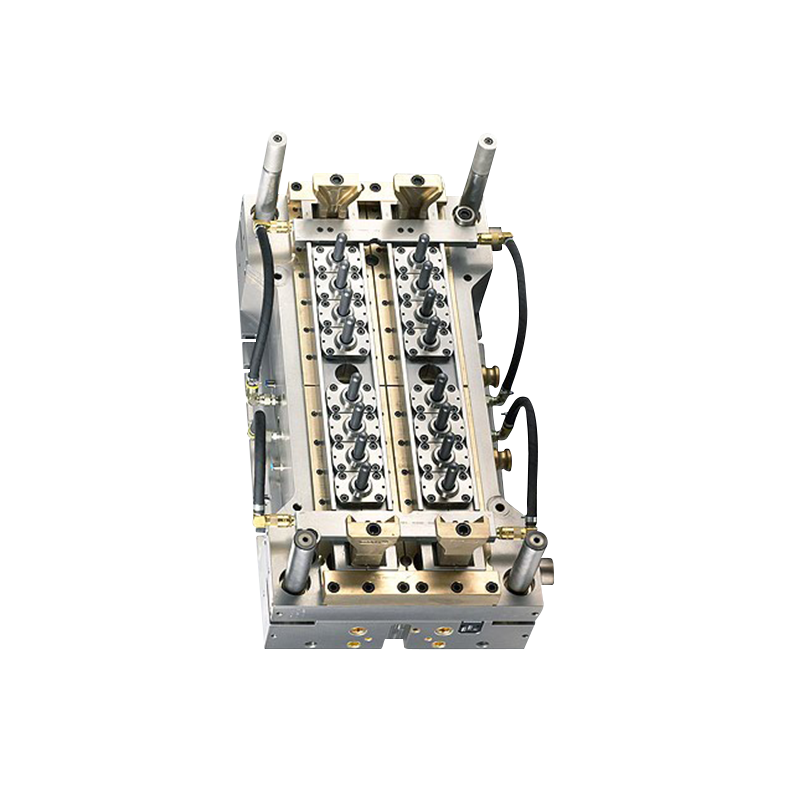

24腔PET瓶胚模具(针阀浇口热流道系统)

|

型号: |

JG-24P |

商标: |

巨光 |

|

发源地: |

中国台州 |

邮寄日期: |

60天 |

|

包装: |

一般包装 |

支付方式: |

T/T & L/C |

|

证明: |

CE, ISO9001:2008 |

出口市场: |

世界各地 |

主要数据

|

瓶坯重量 |

10gr-50gr |

|

颈围 |

28-38mm |

|

模腔 |

48 |

|

模具基材 |

P20钢 |

|

芯/腔材料 |

德国2316钢铁或瑞典S136 |

|

螺丝颈材质 |

德国2316钢铁或瑞典S136 |

|

模具尺寸 |

基于瓶坯样品 |

|

模具重量 |

约2000kg |

|

加热板 |

P20钢 |

|

瓶胚类型 |

没有注射尾部,无需切割 |

|

模具结构 |

独立自锁,自动脱模 |

|

热流道 |

德国HOTSET |

|

隔热帽 |

USA DUPONT |

|

模具寿命 |

2000000次射击 |

|

模具保修 |

1年 |

|

交货时间 |

45-60天 |

|

包装条款 |

标准出口木箱 |

你在找什么?